Introducing Electrochemical Oxidation Wastewater Treatment Modular Unit EOU7240

Wastewater treatment modular unit EOU7240 is Evoaeo’s very first modular unit aimed to application of electrochemical oxidation wastewater treatment in bench scale testing and then feasibility assessment prior to pilot scale electrochemical oxidation wastewater treatment systems, Evoaeo EOU240 is one of the few elite electrochemical oxidation core modular unit at smallest dimensions, and compact size, within various bench scale water treatment product lines.

EOU7240 serve as the core part and basical component of Evoaeo electrochemical treatment system as it could be converted into to larger sizes, designed to fit different electro oxidation cell units to function as electro oxidation electrolyzers and decentralized electro oxidation water treatment equipment, it’s a new approach to realize efficient and innovative electrochemical oxidation remediation of complex industrial effluents. Modular unit EOU7240 employs electrode assembly with seven pieces of boron doped diamond electrodes and 8 pieces of Titanium electrodes, it offer high electrochemical oxidation treatment efficiency with active electrode area approaching 4200 cm2, and maximum current density up to 100 mA/m2.

Unlock the capability of electrochemical wastewater electrolysis with this modular unit. Join us to explore how advanced electrochemical oxidation processes technology provide unmatched removaling efficiency and sustanability, and enhance your treatment processes.

Key Features and Benefits of Wastewater Treatment Modular Unit EOU7240

Designed to Fit Into Existing System

As an efficieny treatment equipment designed for orgnic pollutants removal for tertiary treatment, but yet with compact design, which requires limited space, our modular unit could fit into operating water treatment system. The way in which streams enters the modular unit is controlled in such a way that making field operation simpler.

High Electrochemical Efficiency

With an active electrode area at 4200 cm2, maximum current density at approx 100 mA/m2, modular unit EOU7240 can deliver super electrochemical oxidation removal efficiency toward organic polluants.

Simplified Operation & Maintenance

Given the excellent chemical and mechanic stability, anti-fouling nature of boron doped diamond electrode as core part of the electrochemical oxidation, processes, daily operation and routine maintenance made simple, including refrequent anode material changing and adding of extra chemicals.

Key Characteristics of Water Treatment Modular Unit EOU7240

Electro Oxidation Water Treatment Modular Unit EOU7240 Structures

Electro Oxidation Wastewater Treatment Modular Unit EOU7240 Structures

Electro oxidation wastewater treatment modular unit EOU7240 is designed to fit into electrolytic cell to conduct larger scale wastewater electrolysis, main structures of modular unit EOU7240 are electrode assembly, chemically insert PTFE shell, metal contact parts and accessories

Electro Oxidation Water Treatment Modular Unit EOU7240 Specifications

Anode Material: BDD Electrode with Silicon Substrate

Dimensions: 240*130*3 mm

Quantity: Seven pieces

Cathode Material: Titanium Electrode

Dimensions: 324*150*1.5 mm

Quantity: Eight pieces

Active Surface Area: Up to 4200 cm2

Working Voltage:≤DC~12V

Rated Current:≤ DC~340 A

Net Weight: 8.8 kg

Shell:PTFE

Explore The Future Of Maximum Onsite Industrial Wastewater Treatment Efficiency, Request A Quote On EOU7240

Get Started Now

Find Out Working Mechanism Of Electro Oxidation Water Treatment Modular Unit EOU7240

Electro oxidation water treatment modular unit EOU7240 is the our first core components and unit designed to fit into Evoaeo’s electrochemical oxidation water treatment units and system, what is more is very first electrode assembly with large area boron doped diamond electrode plates and titanium electrodes implemented to conduct pilot sclae electro oxidation treatment of wastewater.

01

Best anode material

Boron doped diamond electrode got extremely high oxygen evolution potential and the widest electrochemical window among all electrodes.

02

Efficient

Superb organic pollutant removal efficiency, resistant to acid and alkali, less fouling, easy to operate and maintenance.

03

Eco-friendly

No extra toxic chemicals need to be added to the electro oxdiation processes. Hydroxyl radicals mineralize organic compounds.

Ready To Explpore More Info About How BDD Electrode Works To Conduct This Electrolytic Water Treatment Processes of Organic Pollutants

Electrolytic Treatment via BDD Electrode

Treatment Results of Wastewater Treatment Modular Unit EOU7240

Electrochemical Oxidation of Petrochemical Wastewater

Electrochemical Advanced Oxidation of Active Pharmaceutical Ingredient

Electrochemical Removal of Dyes and Pigments from Textile Wastewater

Frequently Asked Question About Wastewater Treatment Modular Unit EOU7240

As one of the rising manufacturers specializes in research, development, and all scale implements of advanced electrochemical oxidation water and wastewater treatment products, ranges from wastewater treatment module unit, advanced oxidation wastewater treatment equipment, up to advanced oxidation wastewater treatment system. Check the frequently asked questions about advanced oxidation wastewater treatment modular unit EOU7240, feel free to contact us if you have any further questions, fill out the blanks within the contact us section below or leave a message within the contact us section.

What is electro oxidatin wastewater treatment modular unit/module?

This electro oxidation wastewater treatment modular unit is basically a giant electrode assembly, EOU7240 forms an electrolytic wastewater treatment modular unit with electrolyzer shells, bench scale advanced oxidation wastewater treatment could be conducted on-site once electric current applied, as all the electrode materials are placed in the required positions and wastewater electrolysis is ready to run, MU724 advanced oxidation wastewater treatment module have left space for existing wastewater treatment system connection, piping, sampling, filters, as well as control fittings, switch/pause, and filter valves.

What is advanced oxidatin wastewater treatment system?

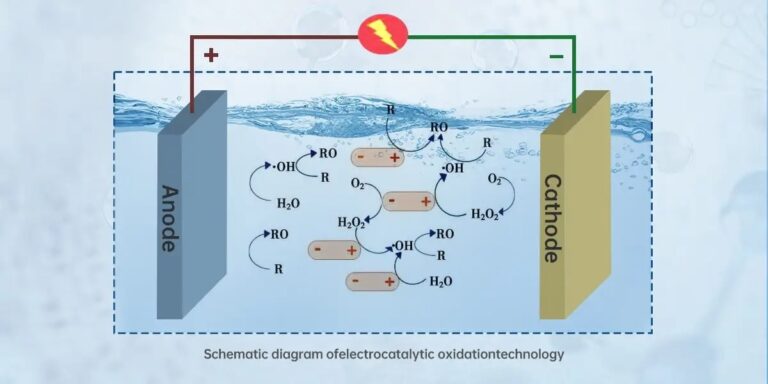

Well, it’s a great question here, wastewater water treatment system which adopt advanced oxidation processes (AOP), a new technology regrade and then eventually remove refractory organic compounds/pollutants, from wastewater, especially industrial effluent streatms, advanced oxidation wastewater treatment system combines electronics, fluid mechanics, electrochemistry, electrolytic treatment of wastewater (wastewater electrolysis), and other related technologies

What are the key factors affecting advanced oxidation wastewater treatment, to this wastewater treatment modular unit and your advanced oxidation wastewater treatment system?

Our technical supprt engineers managed to sort our factors affect the efficiency/outcome of advanced oxidation wastewater treatment here below:

1. electrode materials, advanced oxidation processes(AOP)/redox reactions are largely dependent on the properties of electrode materials, click to check properties of boron doped diamond electrode/bdd electrode and then explore comparison of boron doped diamond electrodes and MMO electrodes here. 2. distances between anode and cathode, proper distances between anodes and cathodes reduce resistance flow of ions, and enhance the mass transfer of ions, which expedited anodic oxidation process. 3. electrolyte compilation affects the conductivity and resistances of electrolyte, therefore efficiency. 4. current density 5. temperature

Interested in Evoaeo EOU7240?

Unleash the full potential of advanced electrochemical oxidation treatment technology in your wastewater treatment endeavors with our dedicated technical support team.

Elevate your experiments with our unmatched customization and stellar service.

Reach out today and let us transform your wastewater treatment needs into bespoke solutions for unparalleled success.

Employing optioneering advanced electro oxidation techniques to pinpoint the most suitable solution.

Enter your information here.