Electro Oxidation Module Electrolyzer Cell EOUE240 for

Greener Organic Wastewater Treatment Solution

Discover features, parameters, mechanisms, and typical applications of advanced electro oxidation module electrolyzer cell EOUE240 and how sustainable advanced electro oxidation processes for wastewater treatment solutions tackle the challenges originates from recalcitrant organic compounds in industrial and commerical effluents and advanced oxidation processes revolutionize water treatment industry via pilot scale onsite organic pollutants degradation.

Introducing Electro Oxidation Module Electrolyzer Cell EOUE240

Module electrolyzer cell EOUE240 is one of the first few commercially available electrolyzer cells/electrochemical electrolyzer systems in the market to reform the water treatment and management industry, EOUE240 employs two sets of modular unit MU724 and one set of PP modular sink.

Treatment modular units include several groups of electrode assembly made of boron doped diamond electrodes and titanium electrodes. The content will introduce unique working mechanism, structures of module electrolyzer EOUE240.

Working Mechanism of Electro Oxidation Module Electrolyzer Cell EOUE240:

Advanced electro oxidation processes technology application for wastewater treatment is how the advanced electro oxidation module electrolyzer cell EOUE240 functions as one of the major commerically available pilot scale EO treatment system within the market.

Boron doped diamond electrode exhibits the largest electrochemical potential window amongst all electrode materials, and remarkable low background current, with unmatched chemical and dimensional stability, boron doped diamond electrode become the ideal electrode material for electrochemical generation of reactive oxygen species such hydroxyl radicals which demonstrate strong electrochemical oxidation pontential and non-selective mineralization of organic compounds. We developed module electrolyzer cell employs boron doped diamond electrodes as the core component, with continuous degradation of recalcitrant organic compounds in mind, advanced oxidation wastewater treatment processes could be conducted under normal temperature and pressure conditions.

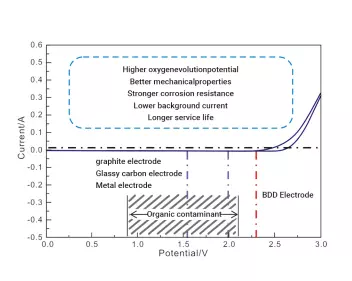

Boron Doped Diamond Electrode Potential Window And Current Comparison With Conventional Electrodes

Boron doped diamond electrodes excels in electrochemical generation of hydroxyl radicals

Boron doped diamond electrode has the widest electrochemical potential window amongst electrode materials, which means a much wider cathodic and anodic potential window lead to higher overpotential for oxygen evolution, increase electrochemical generation of hydroxyl radicals, with remarkable low background current, unmatched chemical and dimensional stability, boron doped diamond electrode become the ideal electrode material for applications of advanced oxidation processes of wastewater treatment.

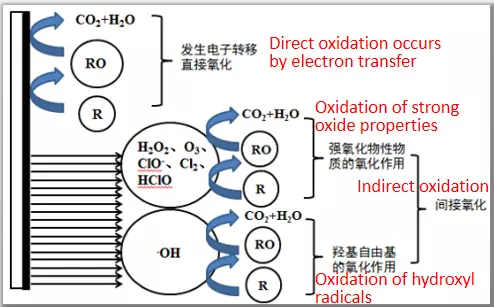

Schematic Diagram and Mechanism of Advanced Electro Oxidation Processes Oxidation Technology (Direct & Indirect Oxidation In Electrolyte and On the Surface of Boron Doped Diamond Electrode)

Electrochemical Advanced Oxidation Processes Via Boron Doped Diamond Electrode Electrolysis

Water, being a polar molecule, exhibits a positive and negative end. During the process of water electrolysis, the positively charged hydrogen atoms are attracted to the negatively charged electrode (cathode), while the negatively charged oxygen atom is drawn towards the positively charged electrode (anode). As a result, the water molecules dissociate into their respective ions: hydrogen ions (H+) at the cathode and hydroxide ions (OH-) at the anode.

The water electrolysis process can be summarized by the following half-reactions:

At the cathode: 2H+ + 2e- -> H2 (hydrogen gas)

At the anode: O2 + 2H2O + 4e- -> 4OH- (oxygen gas)

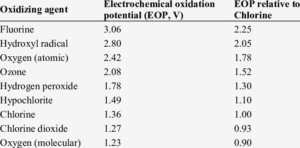

*Potency of oxidizing agents: ranking by electrochemical oxidation pontential(EOP) and EOP relative to Chlorine

OH radicals are recognized as one of the most potent oxidants in existence.

Hydroxyl radical is one of most active oxidizing agents, and it presents non-selective mineralization toward oxidizable molecules for its high electrochemical oxidation potential. Hydroxyl radicals could decompose organic compounds with no concentration, hydroxyl radicals mineralize the vast majority of organic pollutants, especially non-biodegradable compounds such as antibiotics, steroids, BTEX, PCBs, PAHs, APIs, etc. It’s an eco oxidizing agents, as hydroxyl radicals naturally decompose into water (H2O) and oxygen (O2), without leaving behind any harmful materials.

Explore More About Electrochemical Wastewater Treatment via Boron-Doped Diamond Electrode Electrolysis

BDD Electrolysis

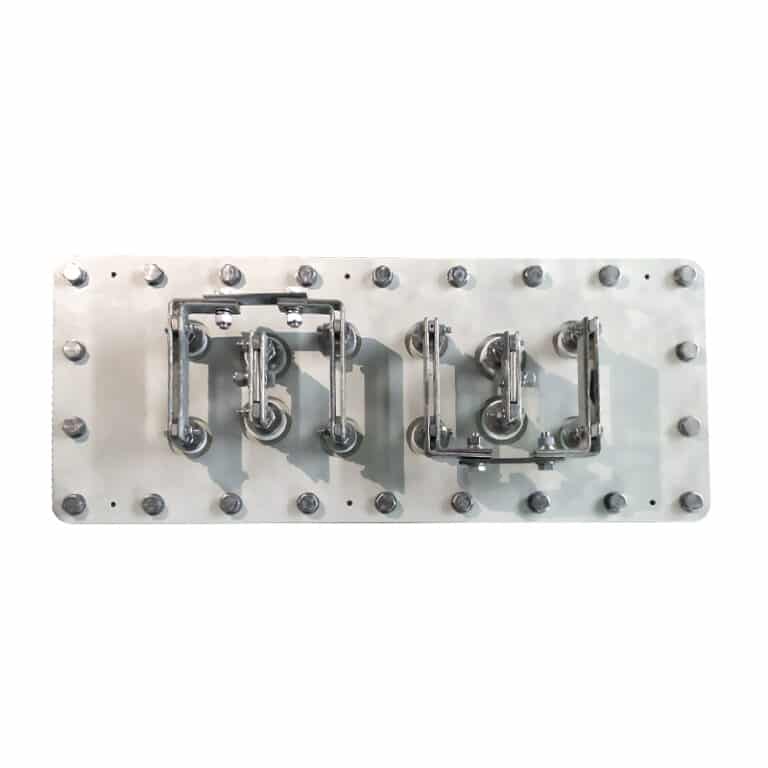

Electro Oxidation Module Electrolyzer Cell EOUE240 Structures

Structures of Electro Oxidation Module Electrolyzer Cell EOUE240

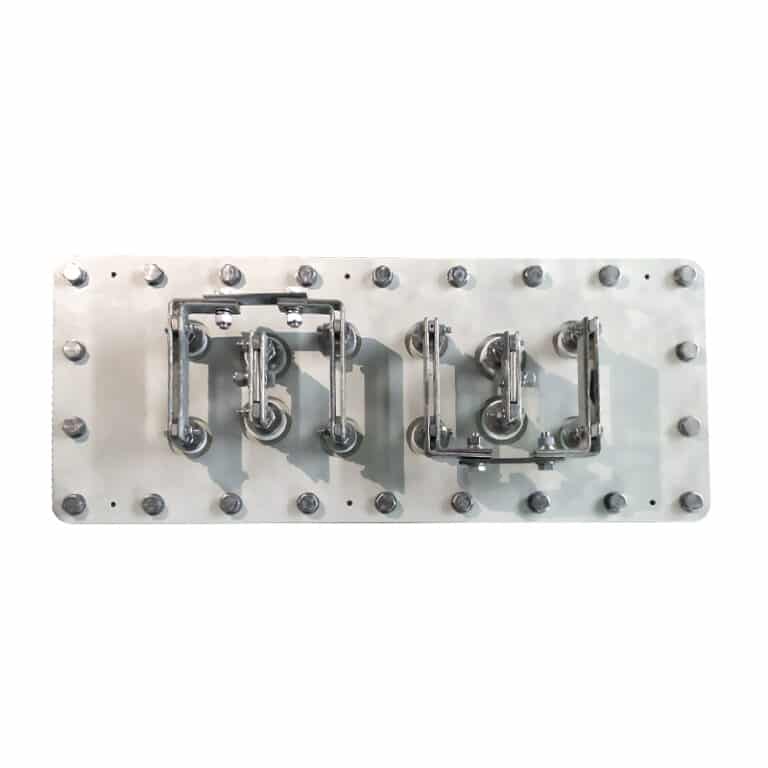

Advanced electro oxidation module electrolyzer cell EOUE240 come with two sets of advanced oxidation treatment module unit MU724, both sets are installed within the cell, and equiped with modular sink, and bracket.

Electro Oxidation Module Electrolyzer Scale Up

Scale-up of advanced oxidation treatment system is critical to the practical application of electrochemical treatment in refractory organic wastewater treatment in full-scale.

Under certain operating conditions and better anode material such as boron doped diamond electrode, and leveraging our professional experience from previous projects and advanced oxidation treatment products, successfully scaled-up electorlyzer cell managed to reduce chemical oxygen demand (COD) of wastewater massively in hours, it desmonstrated much higher performances on organic pollutants removal efficiency.

Electro oxidation electrolyzer cell EOUE240 is very promising in typical refractory organic wastewater treatment.

Click To Get A Free Quote About EOUE240 Right Now

Key Features of Electro Oxidation Module Electrolyzer Cell EOUE240

Versatile Organic Pollutant Removal Efficiency

Advanced oxidation module electrolyzer EOUE240 is engineered for pilot scale thorough removal of organic pollutants thanks to the electrode assembly made of boron doped diamond electrodes and titanium electrodes.

As we mentioned above, boron doped diamond electrode have the widest electrochemical potential window, it could place much higher potential window between cathode and anode, which lead to higher overpotential for oxygen evolution, and eventually increase efficiency of electrochemical generation of hydroxyl radicals and other oxidizing agents.

With an oxidizing agent with second highest electrochemical oxidation pontential, Hydroxyl radicals accomplish rapid and complete oxidation of refractory organic pollutants, transform them into carbon dioxide and water. Organics and nitrogenous compounds are efficiently removed through electrochemical oxidation process.

With multiple electrode assembly and modular unit installed, advanced oxidation module electrolyzer cell EOUE240 demonstratesremoval efficiency toward versatile organic pollutants such as:

Remediation of total organic carbon (TOC)

Chemical oxygen demand (COD)

Total ammonia nitrogen (TAN)

Total nitrogen

Active Pharmaceutical Ingredients (APIs),antibiotics, steroids from pharmaceutical sectors

BTEX,Phenols, TOC, and TPH from petrochemical industries

Typical organic pollutants from lithium-ion battery manufacturing and recycling businesses such as Dimethyl carbonate (DMC), Ethylene carbonate (EC/C3H4O3), Ethyl Methyl Carbonate (EMC), Diethyl carbonate (DEC/C5H10O3) and etc.

With remarkable treating capability and unparalleled removing efficiency to eliminate persistent and bio-refractory organic contaminants, advanced oxidation module electrolyzer cell EOUE240 sets a new standard for wastewater treatment versatility. It is the ideal equipment for applications of advanced oxidation processes of wastewater treatment to treat bio-refractory organic wastewater, especially those from industrial effluents, an alternative approach to replace conventional treatment methods such as biological.

Chemical Free Advanced Electro-Oxidation Treatment

Advanced oxidation module electrolyzer cell EOUE240 distinguishes itself by employing modular unit with boron doped diamond electrode assembly for advanced electrochemical oxidation of wastewater treatment.

Unlike Fenton, a conventional advanced oxidation process technology, there is no need to add catalyst, no challenge with optimization of process parameters, what is more, there is no need for adding of extra hazardous chemicals to achieve optimal degradation efficiency.

Cost-efficient electrolytes in minimal volumes drive this clean and effective process, significantly reducing operational costs and addressing concerns related to chemical handling, storage, and possible environmental impact.

Pollution-Free Contaminant Solution

Embracing an inherently “clean” electrochemical process, this electrolyzer cell produces no secondary pollution or harmful byproducts. The reaction products are fully oxidized forms of targeted organic pollutants, ensuring an environmentally friendly and sustainable wastewater treatment solution.

Inherent Design Simplicity and Operation

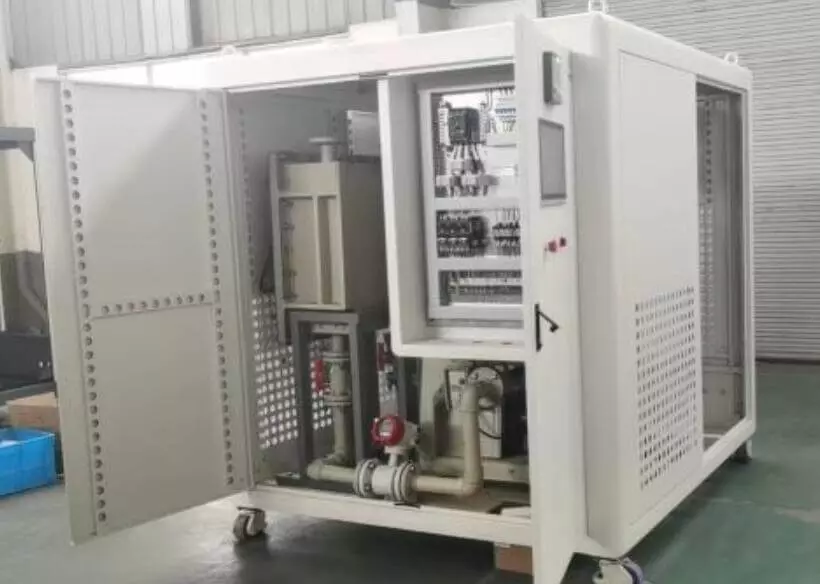

Advanced oxidation module electrolyzer cell EOUE240 is designed to conduct electrochemical oxidation water treatment in water treatment facilities and manufacturing sites, with modular treatment units and flow cell, modular sinks, brackets, and pipes, power outlet combined, customers can conduct onsite water treatment by connecting the electrolyzer cell to current treatment equipments and applying electric current, right on arrival, no catalyst or chemicals required, no sludges or solids generated as within chemical or biological processes.

Given the unparalleled chemical and dimensional stability of premium quality boron doped diamond electrode, there is way less chance of fouling, which simplified operation and require less maintenance.

Electro Oxidation Module Electrolyzer EOUE240 Specifications

Electrode Assembly & Modular Unit:

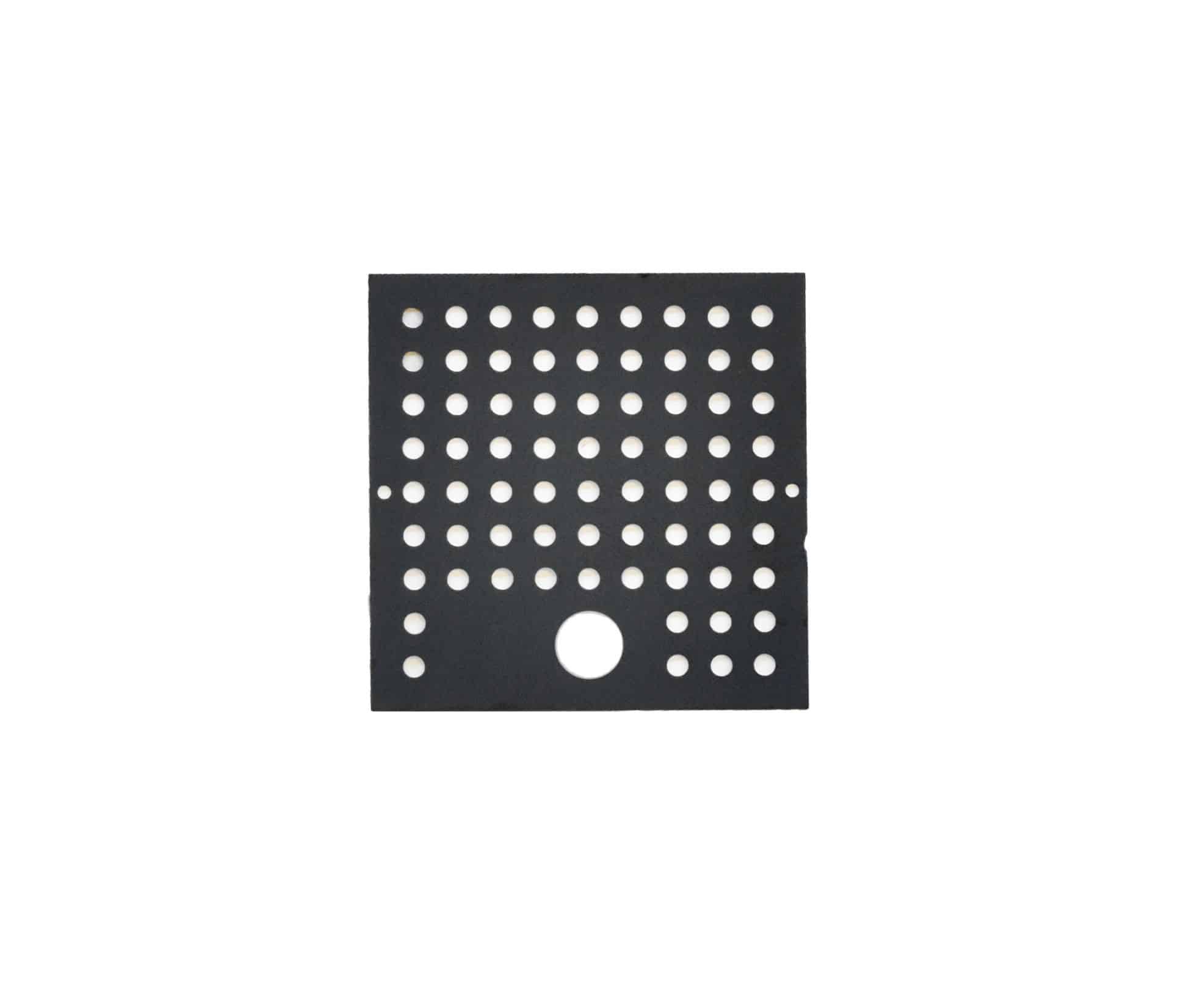

Electrolyzer cell EOUE240 employs two sets of modular unit MU7240, each modular unit has seven piecs of boron doped diamond electrodes with silicon substrate, and eight pieces of titanium electrodes.

Electrode Assembly Parameters:

Anode Material: Boron doped diamond electrode

Anode Dimensions: 240*130*3 mm

Anode Quantity: Fourteen pieces

Cathode Material: Titanium Electrode

Cathode Dimensions: 324*150*1.5 mm

Cathode Quantity: Sixteen pieces

Flow Cell:

Overall Dimensions: 960*360*450 mm

Sealed Electrode Surface Active Area: Up to 8400 cm2

Input Power:DC 500A /20V

Current Density: 55-100 mA/cm2

Net Weight: 65 kg

Download Electrolyzer Cell EOUE240 Brochure

Applications of Electro Oxidation Module Electrolyzer Cell EOUE240

Based on expertises of boron doped diamond fabrication capabilities & years of experiences wiht advance electrochemical oxidation process water and wastewater treatment technology, the advanced eletro oxidation module electrolyzer cell EOUE240 is ideal for a wide range of wastewater treatment applications, including:

Industrial Effluent Treatment

Electro oxidation module electrolyzer cell EOUE240 is one of our modular water and electro-oxidation wastewater treatment solutions designed for industries and businesses, manufacturers dealing with recalcitrant organic chemicals in their effluents.

Check the major organic pollutants we have applied advanced electrochemical oxidation processes treatment technology within treatability assessment, treatment methods evaluations and previous projects:

Active Pharmaceutical Ingredients (APIs) and process water from pharmaceutical manufacturers.

Special chemicals such as pesticides,herbicides and insecticides, typical refractory organic pollutants found in agricultural wastewater.

Hydrophilic & Hydrophobic organic pollutants.

COD degradation to extremely low level.

Other hazardous organic compounds.

EOUE240 encompasses:

Organic industrial effluents/wastewater treatment Safe water reusage

Environment regulation compliance Reduce wastewater incineration

No sludge/solid

Distributed Wastewater Treatment Solutions

With mobility and compatibility in mind within the design and development processes, module electrolyzer EOUE240 is set to be operating in stand-alone mode, with its compact design, the scalable electrochemical oxidation treatment electrolyzer cell could be installed and ready to operate within limited spaces in water treatment facility and manufacturing sites, therefore people can scale advanced oxidation treatment system up for increasing demands.

Environmental Remediation Projects & Explore Complete Bio-refractory Pollutants Removal

EOUE240 could be a part of environmental remediation projects as advanced electrochemical oxidation processes represents a fundamental change in addressing organic pollution concerns. Unlike conventional wastewate treatment methods, this innovative technique relies on electrochemical reactions to decompose organic compounds at the molecular level, ensuring a thorough and lasting degradation. EOUE240 is a new approach to a sustainable treatment as it minimizes the use of toxic chemicals, therefore reducing the environmental impact associated with remediation efforts.

Advanced electro oxidation processes emerge as an alternative wastewater treatment methods to replace conventional biological treatment as AOP could remove most of the bio-refractory organic pollutants from effluents.

Get A Free Water Profile Analysis And Treatability Check Explore Recommended Water Treatment Equipment Solution

Free Water Analysis

Relevant Products of Advanced Electro Oxidation Module Electrolyzer EOUE240

As one of the major manufacturers of boron doped diamond electrode, Evoaeo always improve research and development of boron doped diamond electrode and field application of this superb electrode material, especially in organic wastewater treatment. Module electrolyzer cell EOUE240 are results of research and component developments, process parameters optimizations, feasibility analysis, and scalbility exploration, we manage to bring advanced electrochemical water treatment systems and solution at differnt scales to cater to different markets and industries. Explore boron doped diamond electrode and trial scale, bench scale water treatment modules, pilot scale water treatment systems designed to meet specific experimental needs, and commerically available solutions with already achieved results.

Boron doped diamond electrode demonstrates exceptional removal efficiency, enduring stability, and remarkable chemical, remove refractory organic pollutants via anode oxidation.

BDD Electrode

Read More

Test module was designed to offer all-in-one solutions for those who conduct small scale wastewater electrolysis tests within wastewater treatment plants, manufacturing facilities, anywhere with access to power source. Simple,reliable and screening.

Test Module

Read More

The beaker trial module is designed for small scale wastewater electrolysis in lab or conducting field tests. Compact design, precise engineering and redefined efficiency with versatile applications.

Beaker Trial Module

Read More

We developed wastewater treatment system and pilot modules based on boron doped diamond electrode to complete degradation of organic pollutants found in wastewater.

Treatment System

Read More